Designing Global Cooperatives – One Community Weekly Progress Update #437

Designing global cooperatives is a lot easier with a plan that includes people globally and is grassroots implementable. One Community is creating this plan and it includes open source and free-shared sustainable designs and tutorials for food, energy, housing, education, for-profit and non-profit economic design, social architecture, fulfilled living, global stewardship practices, and more.

- Here’s our project overview

- Here’s our world-change methodology

- Here’s how this becomes self-replicating

- Here’s how we are open source and free-sharing all the do-it-yourself designs

OUR MAIN OPEN SOURCE HUBS

Click on each icon to be taken to the corresponding Highest Good hub page.

One Community’s physical location will forward this movement as the first of many self-replicating teacher/demonstration communities, villages, and cities to be built around the world to help designing global cooperatives. This is the August 8th, 2021 edition (#437) of our weekly progress update detailing our team’s development and accomplishments:

Designing Global Cooperatives

One Community Progress Update #437

DONATE | COLLABORATE | HELP WITH LARGE-SCALE FUNDING

CLICK HERE IF YOU’D LIKE TO RECEIVE AN EMAIL EACH WEEK WHEN WE RELEASE A NEW UPDATE

YOU CAN ALSO JOIN US THROUGH SOCIAL MEDIA

Designing Global Cooperatives

ONE COMMUNITY WEEKLY UPDATE DETAILS

DESIGNING GLOBAL COOPERATIVES – HIGHEST GOOD HOUSING PROGRESS

One Community is designing global cooperatives through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

One Community is designing global cooperatives through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

-

-

- Learn about: Our Upcoming Crowdfunding Campaign

- Learn about the different village models: 7 Sustainable Village Models

- Visit the open source portals for the first two: Earthbag Village OS Hub | Straw Bale Village OS Hub

-

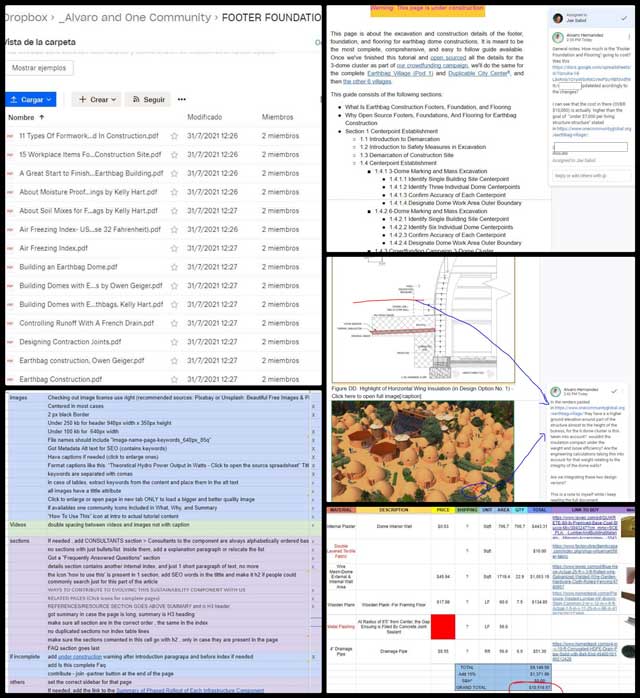

This week the core team continued working on the “Earthbag Construction Footers, Foundation, and Flooring” live page as a part of designing global cooperatives. The web editor in our team finished editing the technical part of the One Community´s Earthbag Dome Footer Foundation and Flooring.

He then began the final comprehensive read he does before submitting it to our final grammar, spelling, and clarity reviewer. In doing so he spotted some inconsistencies around the different earth dome related pages, so we need to address those first. The pictures below share some of this work and what he found.

Designing Global Cooperatives – Earthbag Construction Footers Foundation and Flooring

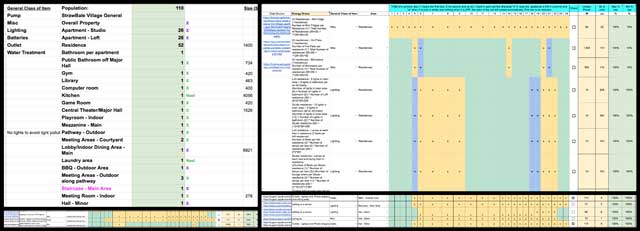

The core team also continued work on the energy analysis, for the solar farm and microgrid designs. We finished the electrical estimates for the residences, indoor and outdoor dining areas, public bathroom off the Major Hall, Minor hall, and staircase for the Straw Bale Village. We also started working on the HVAC electrical demands. See related pictures below.

Designing Global Cooperatives – Energy analysis for the solar farm and microgrid designs

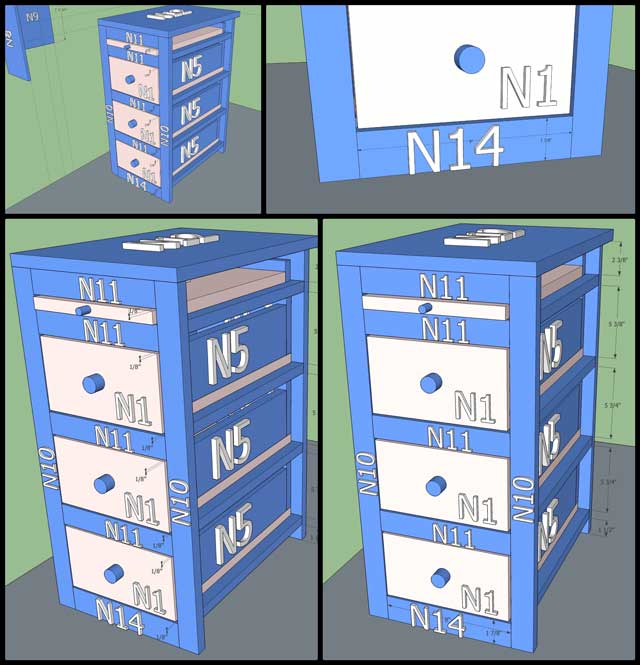

And the core team corrected misalignment of some parts of the night stand that is part of the Murphy bed design. We provided new dimensions for affected parts to the volunteer that is updating the Murphy Bed Assemble Instructions.

Designing Global Cooperatives – Murphy bed design

Dean Scholz (Architectural Designer) continued helping with the Earthbag Village (Pod 1) 4-dome cluster designs. This was week #226 of Dean’s work and finished solving the lighting issue for the lamps and produced this test render:

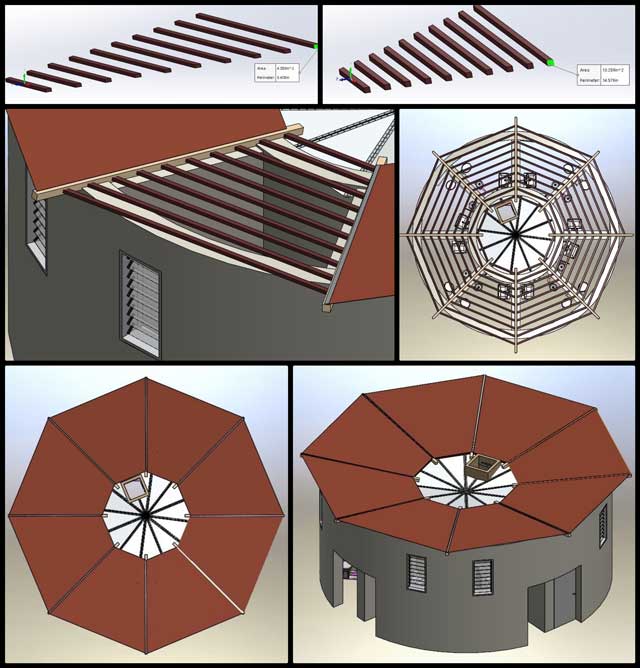

Jose Luis Flores (Mechanical Engineer) completed his 55th week helping and finishing the Net-zero Bathroom component of the Earthbag Village.

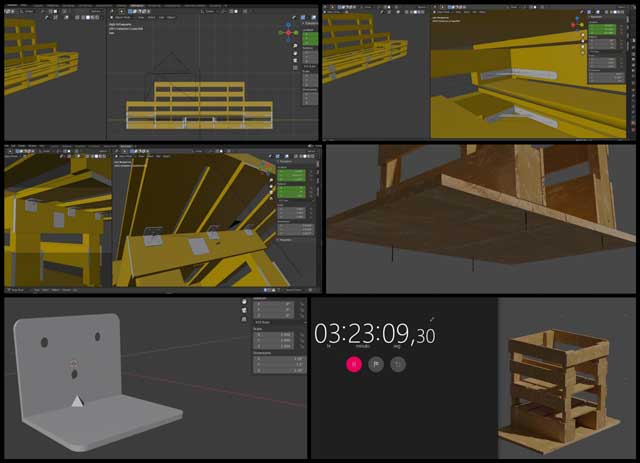

This week Jose Luis continued updating the exterior roof rendering of the net-zero bathroom. The updates included resizing the cross sectional dimensions of the tangential support beams attached to the radial beams.

The previous design utilized 4 by 4 wooden beams, but was updated to use 2 by 2 wooden beams. This decision was made because of the reduced cross section of the radial beams, which in turn was caused by the reduction of roof panel weight.

The difference in density between galvanized steel (7.14 g/cm3) and galvalume (3.75g/cm3) had not been previously taken into account. The advantage of the weight reduction is the reduction in needed support for the roof panels and the structure itself.

The amount of lumber needed is also consequently reduced by the weight savings. The references needed for the positioning of the components in the rendering had to be heavily revamped due to these changes as well. The pictures below show some of this work.

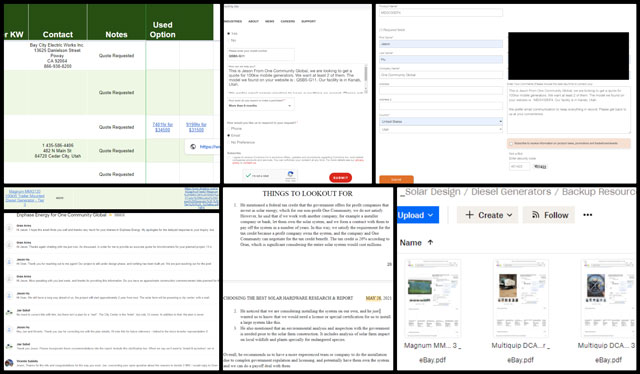

Jeson Hu (Aerospace Engineer) completed his 22nd week helping with research related to the solar microgrid design, sizing, and cost analysis specifics.

This week, Jeson communicated with the Micro Inverter company representative, Oran, regarding the inverter quote. Oran gave some professional advice on One Community’s solar farm project that Jeson added to the report. He then continued the diesel generator research and sent quote requests to all the companies that he researched.

Jeson also researched used diesel generator options. He added the link to the used diesel website and PDFed the website into the dropbox. The pictures below share some of this developing work.

Daniela Andrea Parada (Civil Engineering Student) completed her 16th week helping with the Sustainable Roadways, Walkways, and Landscaping tutorial development. This week Daniela continued working on the Parking Lot Design through AutoCAD.

She made alterations to the parking lot design based on team feedback. Various aspects were changed such as the angle of the parking stalls, adding a loop, and proposing stop sign locations. Pictures of some of this work are below.

Aidan Geissler (Sustainability Researcher) completed his 14th week helping with 2nd-to-final review, feedback, and content editing. Aidan was excited to return to the team after conducting avian surveys in the Southwest for 3 months.

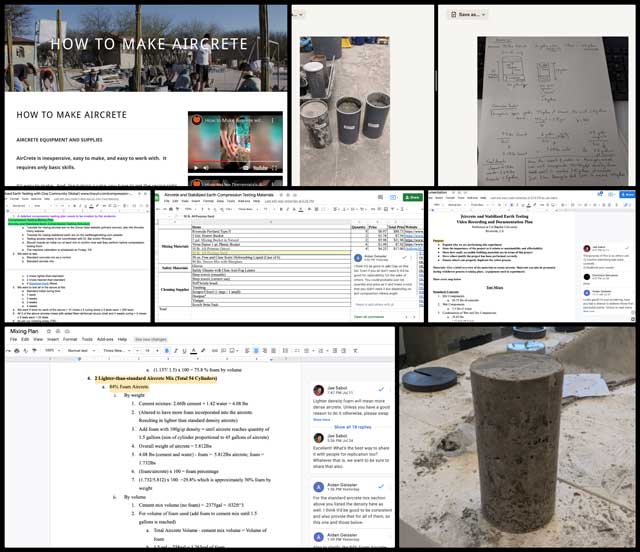

This week he supported the group working on Aircrete and earthbag compression testing. He reviewed their research, testing plans, cleanup plan, and photo and video documentation.

He provided questions, comments, suggestions, and concerns to guide the development of the testing plan and documentation of the process. Pictures below are related to this work.

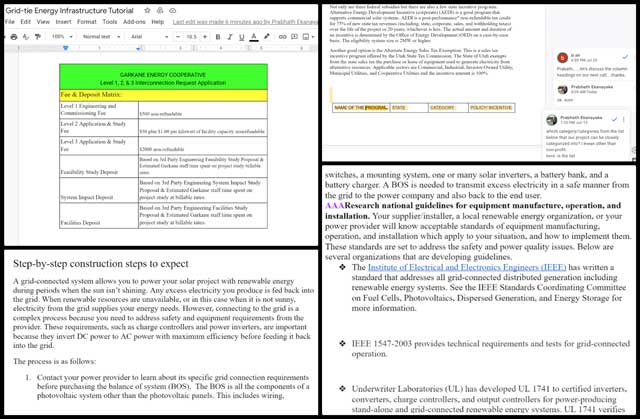

Prabhath Ekanayake (Electrical Engineering Assistant) completed his 9th week working on the grid-tie connection details for our solar microgrid designs.

This week Prabhath continued development of the grid tie tutorial by completing the assigned sections from the core team and did some modifications for my writing. Below are some images related to this work.

Nicholas K. de León (Project Management Adviser) completed his 8th week helping with review of Highest Good Housing research and related tasks. This week Nicholas focused on direct edits, smoothing out the research and fixing grammatical/spelling mistakes to improve readability.

It seems that many of the documents are simultaneously getting closer to being finished, while additions (apart from changes or edits) take the docs back a couple of steps. This is completely expected, only to be noted because it means that some tracking and backtracking is needed on Nicholas’ and other editors’ part.

The phases these documents go through are less distinct, naturally, with this current “phase” being a mixture of many different ones: writing, editing, supplementing, and in some cases reordering and restructuring.

After taking the time to re-read most of the six documents, Nicholas felt that the vast majority of the apparent minor issues had been solved, with the inability to find a lot of errors being a welcome sign.

Thus, this week will be spent returning to more major issues like suggestions for clarification, and making edits, where needed, to large formatting problems. Pictures below show some of this work-in-progress.

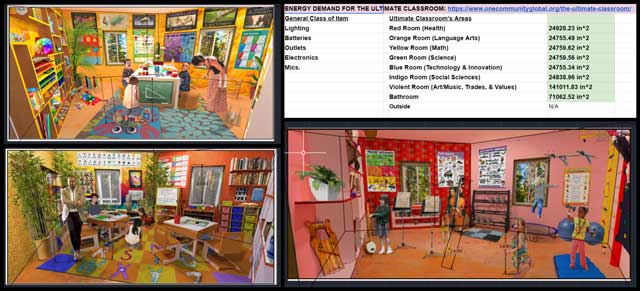

Frank Roland Vilcapaza Diaz (Mechanical Engineer) completed his 7th week helping with the Earthbag Village energy specifics. This week Frank worked on estimating the areas of the rooms of the ultimate classroom to get an approximate energy demands on lighting for them.

He also continued working on the energy demand for the ultimate classroom. The pictures below relate to this.

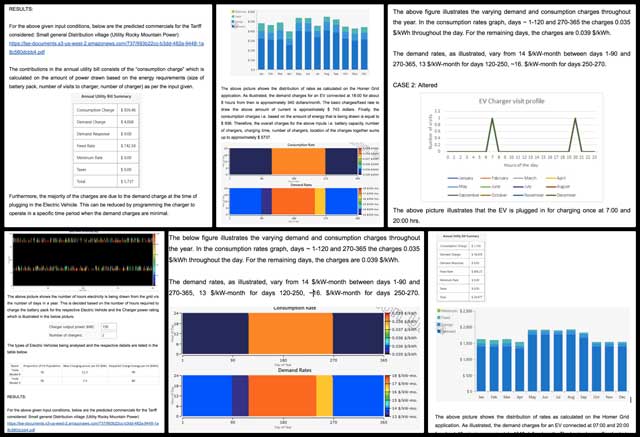

Shreyas Dayanand (Battery Research Engineer) also completed his 6th week in helping with the solar microgrid design specifics related to electric vehicles and battery sizing.

This week, Shreyas ran a more realistic scenario for the EV charging setup for 2 cases: DC Fast Charging and AC Charging. He gave detailed descriptions for the analysis and results and plotted the EV charger visit profile.

Shreyas also made basic conclusions on the commercials of the same. Pictures below relate to this work-in-progress.

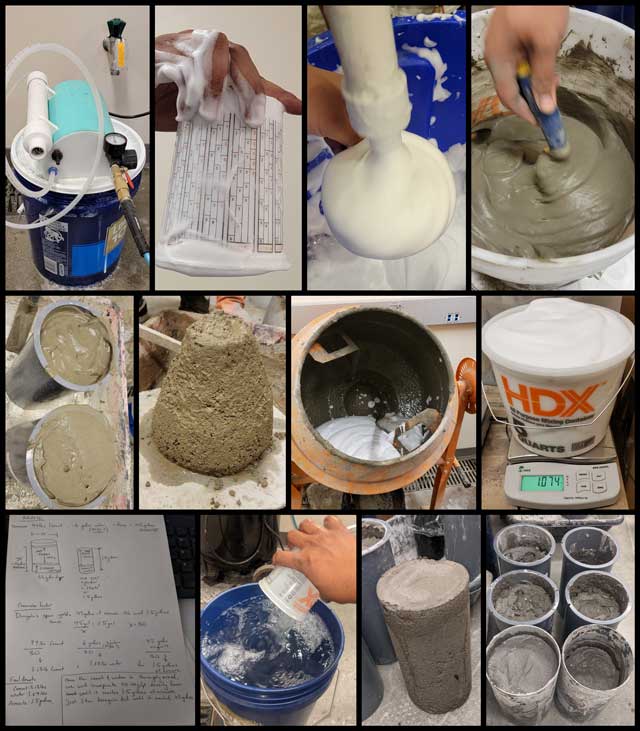

The Compression Team consisting of Dominick Banuelos (Civil Engineering Intern), Jarot Tamba (Civil Engineering Intern), John Paul D. Matining (Civil Engineer Intern), and Marcus Nguyen (Civil Engineering Intern) completed their 4th week in helping with the Aircrete and earthbag compression testing.

This week they worked together to create a standard test cylinder for each of the 3 mixes: aircrete, compressed earth, and concrete. After a few weeks testing and experimenting, the group thinks they have their concrete and stabilized earth portions of the project mostly figured out.

These mixes were created to replicate what the final mix will be in terms of how much of each ingredient is added. The team also worked to make a video of how to do each mix such as measuring out ingredients, pouring ingredients together and mixing them, pouring the mixes into the cylinders, etc.

One of the biggest issues that the group have been trying to figure out is in regards to the aircrete. The issue with the aircrete is that once it has been poured into the cylinder and it sits there for a while, the mix shrinks down either a quarter of the way down or half way down.

Further research was done to understand why this was happening and what could be a solution. The group believes that there is something amiss about the measurements or the mixing process and will continue testing new approaches next week.

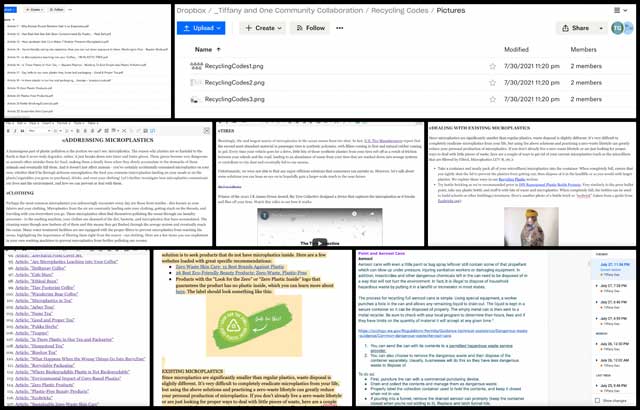

Tiffany Gao (Sustainability/Plastics Researcher) completed her 3rd week as a researcher, reviewer, and web developer. This week Tiffany began reading more about addressing non-recyclables, specifically about gas turbines and plasma gasification while edits were being made on her plastic recycling sections.

Following edits, she transferred those edits of her documents to the WordPress website, spending some time relinking titles/headings, adding the videos and compressing photos. Tiffany also backed up her remaining sources, links and pictures into Dropbox and the Resources list on her WordPress draft. The pictures below share some of this developing work.

Designing Global Cooperatives – Addressing Non-Recyclables

DESIGNING GLOBAL COOPERATIVES – DUPLICABLE CITY CENTER PROGRESS

One Community is designing global cooperatives through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

One Community is designing global cooperatives through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

-

-

- Learn about this building and it’s function: Duplicable City Center Open Source Hub

-

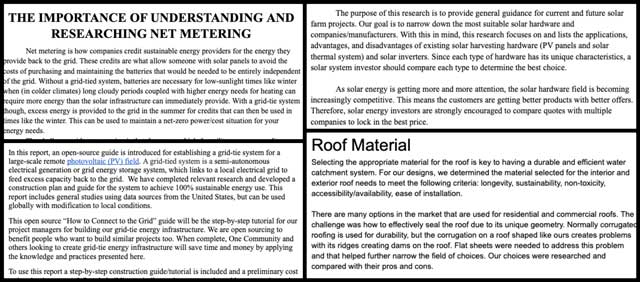

This week the core team continued editing the Grid-tie Energy Infrastructure Tutorial from Grid Connection Details and Solar Incentives and Tax Credits, through page 14.

Designing Global Cooperatives – Grid-tie Energy Infrastructure Tutorial

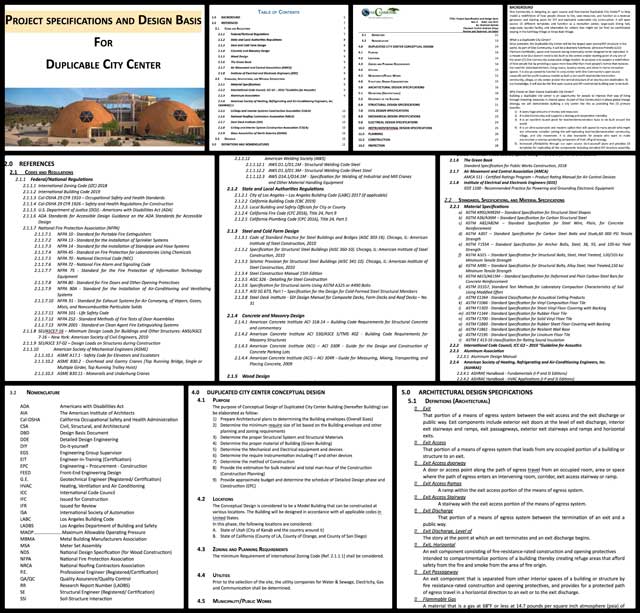

The core team also worked on the Duplicable City Center Project Specification, and Design Basis documentation.

This week we completed the initial table of contents and significant content additions to the sections including Background, References, Definitions and Nomenclatures, Duplicable City Center Conceptual Design, and Architectural Design Specifications.

About 16 pages in total. Pictures below share some of this work-in-progress.

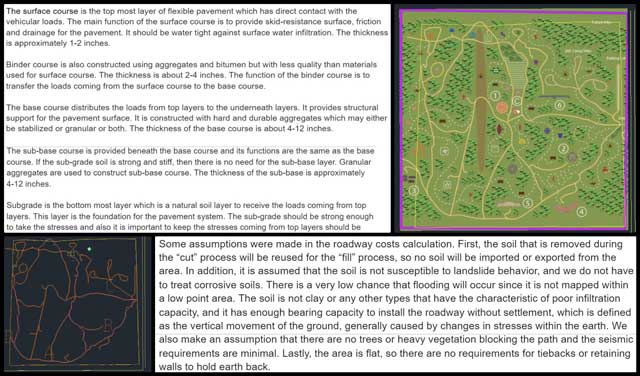

Carol Nguyen (Civil Engineer) also completed her 15th week helping with the Sustainable Roadways, Walkways, and Landscaping tutorial development.

This week, Carol worked on the CAD drawing of the master plan to estimate the length of each roadway type for the roadway cost calculation. She attached the overlay of the background image into CAD and made it to scale. Carol drew the roads of the master plan image into the CAD drawing so it can be used to calculate the length of the roadway.

She also wrote the description for flexible pavement layers and their functions to better explain the cross section drawings. The pictures below share some of this developing work.

Neel Shanbhag (Control Systems Electrical Engineer) completed his 9th and final week helping with the Duplicable City Center Electrical designs. This week Neel completed the power and energy needs for various structures in the Duplicable City Center. This included estimating the hours that each appliance will be used for summer and winter. Pictures related to this work are below.

John Aquino (Electrical Engineer) also completed his 5th week helping lead the Duplicable City Center Electrical designs. This week, John produced electrical lighting sheets. Pictures below show some of them.

Venus Abdollahi (Architectural Designer) completed her 4th week in helping with finishing the Duplicable City Center roof designs. This week Venus completed the City Center Living Dome roof and the Copula roof. For detailing the roof, she used Revit to create details and callouts.

She also created the 3D isometric section of the roofs and she added different layers of materials to achieve a 62.27 R-value for the Copula roof and 75.1 R-value for the City Center Living Dome roof. See pictures below.

And Carlos Lillo (Engineering Technician) also completed his 4th week in helping with the pallet furniture designs for the Duplicable City Center guest rooms. This week Carlos updated the brackets for the Pallet Table, added new brackets to the pallet bed, and included animation of screws for both items.

Second-level animations are in process for the Pallet Chair. For the Pallet Table he generated the first half of the final render, which took about 9 hours. From here on forward he’ll generate renders with a faster engine until everything is approved and then final renders will be produced. Pictures below are related to this work.

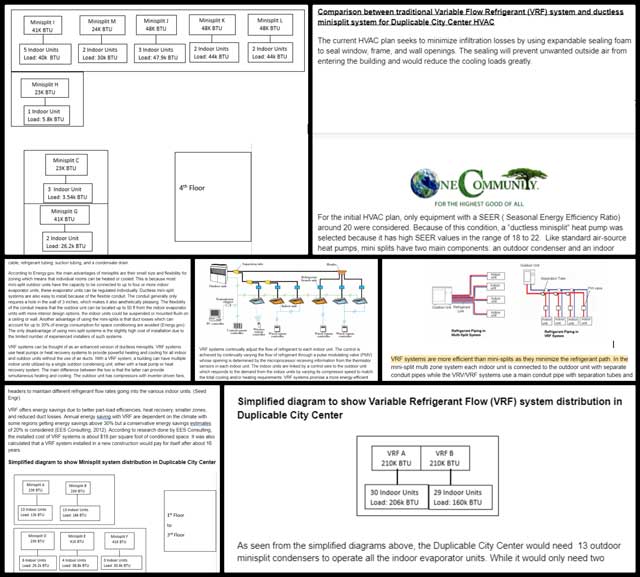

Ibukun Shogbamu (Junior Mechanical Engineer) completed his 2nd week working on the City Center HVAC Designs. This week Ibukun completed a research paper needed to make an informed choice regarding the HVAC system of the Duplicable City Center and submitted it for review and feedback.

The paper describes and compares the current ductless minisplit system for cooling and heating the center and an alternate Variable Refrigerant System. He compared the expected costs, efficiency, and ease of maintenance of both systems. The pictures below share some of this developing work.

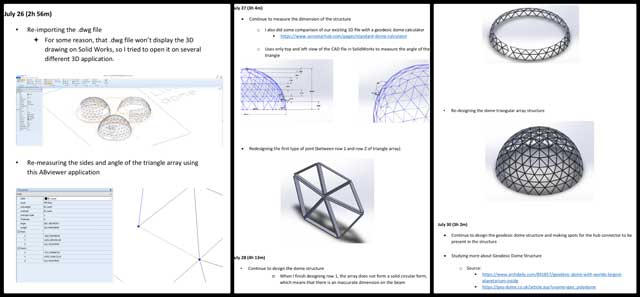

Andrew Wilbert Vidianto (Mechanical Engineer) completed his 2nd week working on the Duplicable City Center connectors we’ll use to build the domes.

This week’s focus was mostly redesigning the Geodesic Dome structure by building it using the 2” x 12” of LVL beam using SolidWorks. A proper LVL beam dome structure with a correct measurement and dimension completion is necessary before designing the beam connectors. Pictures below are related to this work.

DESIGNING GLOBAL COOPERATIVES – HIGHEST GOOD FOOD PROGRESS

One Community is designing global cooperatives through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

One Community is designing global cooperatives through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

-

-

- Learn about the structures: Hoop House Hub | Aquapini & Walipini Open Source Hub

- See what we’ll be growing: Gardens & Hoop Houses | Large-scale Structures | Food Forest | TA

-

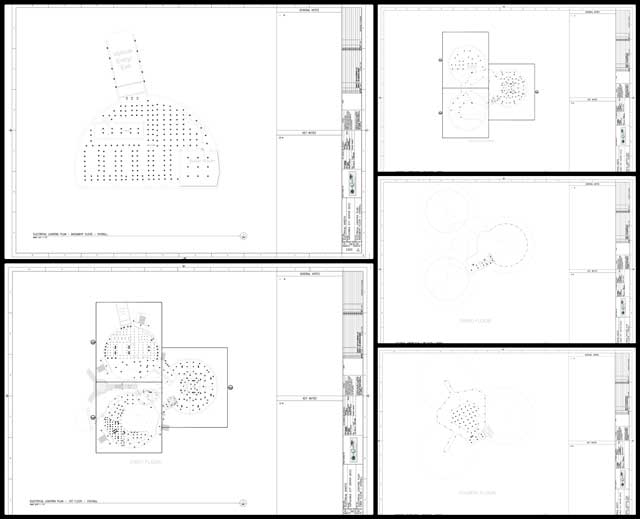

This week the core team continued creating updated SketchUp models for the final designs of the Aquapinis/Walipinis. This week we continued designing the central area of the Aquapini.

In the far west resting area we designed a curved water pool with a wooden arched bridge, a pipe planter over the long bench and a rock/wood sitting bench. We placed flat stepping stones for the walking path and different plants all around the resting area. Pictures below are related to this work.

This week Qiuheng Xu (Landscape Designer) completed her 44th week volunteering helping with the Aquapini & Walipini external landscaping details.

This week Qiuheng focused on modifying the topography and entry way of the North and South structures. You can see below some of the feedback she addressed and pictures of her changes.

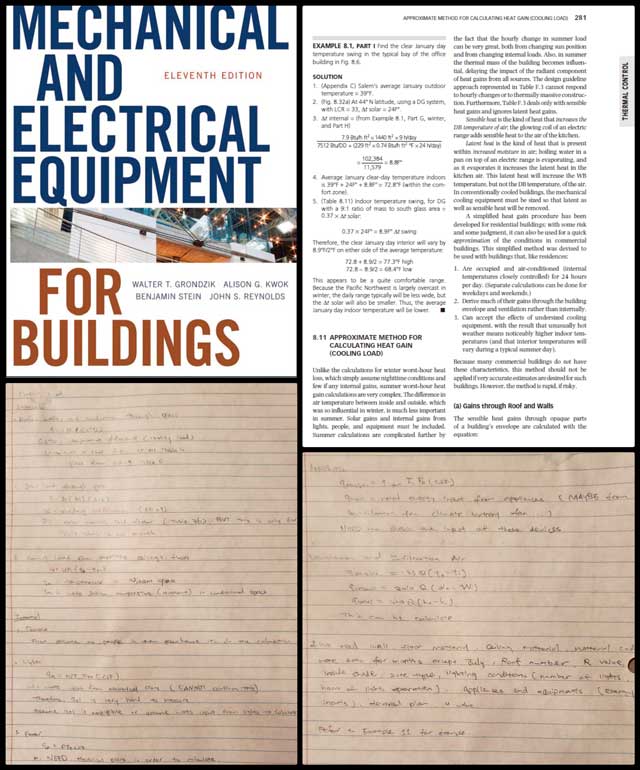

Qisheng Rong (Mechanical Engineer) completed his 4th week helping with the development of the climate battery designs for the Aquapini/Walipini structures.

This week Qisheng researched the CLTD/CLF method to calculate the cooling load of Walipini 3 and made some assumptions to simplify the calculation.

He also found a sustainability textbook called “Mechanical and Electrical Equipment for Buildings” to help him understand and provide him more data and insight into calculating cooling loads like this. The pictures below are related to this work.

DESIGNING GLOBAL COOPERATIVES – HIGHEST GOOD EDUCATION PROGRESS

One Community is designing global cooperatives through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students.

One Community is designing global cooperatives through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students.

This component of One Community is about 95% complete with only the Open Source School Licensing and Ultimate Classroom construction and assembly details remaining to be finished. We’ll report on the final two elements to be finished as we develop them.

With over 8 years of work invested in the process, the sections below are all complete until we move onto the property and continue the development and open sourcing process with teachers and students – a development process that is built directly into the structure of the education program and everything else we’re creating too:

- Program Overview: Education Open Source Hub

- How the components work together: How to use the Education for Life Program

- Lesson Plans for Life – Lesson Plans How-to

- Foundations of Outstanding Leaders, Teachers, and Communicators

- Curriculum for Life

- Teaching Strategies for Life

- Learning Tools and Toys for Life

- Evaluation and Evolution

Highest Good Education: All Subjects | All Learning Levels | Any Age – Click image for open source hub

DESIGNING GLOBAL COOPERATIVES – HIGHEST GOOD SOCIETY PROGRESS

One Community is designing global cooperatives through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

One Community is designing global cooperatives through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

-

-

- Read the Highest Good society overview: Highest Good Society

- Learn about the model for fulfilled living and sharing: A Day in the Life

- Learn about the 4 economic models: RBE | For-profit | Non-profit | Entrepreneurship

- Learn about our open source community collaboration and management software: The Highest Good Network

-

This week the core team completed 26 hours managing One Community emails, social media accounts, interviewing potential new volunteer team members, and managing volunteer-work review and collaboration not mentioned elsewhere here.

The picture below relates to this. We also did more testing and bug identification within the Beta version of the Highest Good Network software.

Jaime Arango (Graphic Designer) completed his 34th week, creating graphics for these blogs and our related YouTube video previews. This week Jaime created images for weekly progress updates #512, #513, #514, #515, and #516.

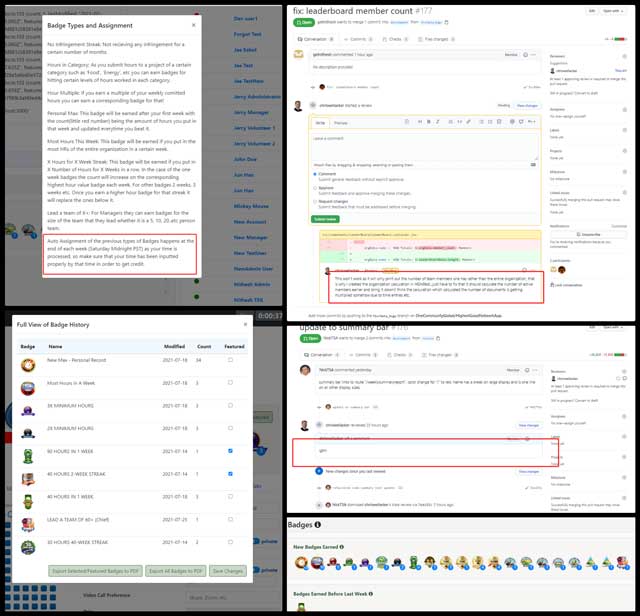

Chris Weilacker (Software Engineer) completed his 34th week working on the Highest Good Network software.

Chris worked on testing the auto-assignment functionality a second time, as well as adding text to describe the timing of the badge auto-assignment each week and demoed the project for a video on the badge functionality and double checked that volunteers can not change their count and/or delete the badges from the report button.

Chris also added a space after the description text on the report. Although the badge testing did not work as perfectly as expected the error was in the fact that someone else was running the backend locally for the dev environment which double-counted the badge count increases on certain badges, and on the new category badges.

For the economics category which Chris’s dev-admin account did not earn last week due to him not inserting enough hours. It got two badges as the code added in the badges.

It worked as expected on upgrading the badges from 100 to 200 due to that code replacing badges instead of adding badges, so, all-in-all, it worked as expected and this would not be an issue on the beta or production site as there is but one server running. Pictures below are related to this work.

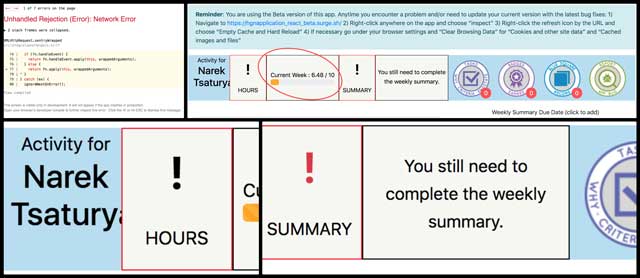

Narek Tsaturyan (Software Engineer) joined the team and completed his 1st week working on the Highest Good Network software. This week Narek worked to set up the local environment.

Once he completed the orientation and setup process he continued development of the summary bar component. Narek worked to improve some of the spacing issues, added links, refactored some code, and added padding into the text to improve UI. The pictures below are related to this work.

AND WE PRODUCED THIS WEEKLY UPDATES BLOG – CLICK HERE TO SUBSCRIBE

FOLLOW ONE COMMUNITY’S PROGRESS (click icons for our pages)

INVESTOR PAGES

GET INVOLVED

DONATE ● WAYS ANYONE CAN HELP ● MEMBERSHIP

CLICK HERE FOR ALL PAST UPDATES

One Community

One Community

Connect with One Community