Helping People Create a Sustainable World – One Community Weekly Progress Update #401

One Community is helping people create a sustainable world through open source sustainability plans covering all aspects of sustainable living. They include food, energy, housing, education, for-profit and non-profit economic design, social architecture, fulfilled living, global stewardship practices, and more.

- Here’s our project overview

- Here’s our world-change methodology

- Here’s how this becomes self-replicating

- Here’s how we are open source and free-sharing all the do-it-yourself designs

OUR MAIN OPEN SOURCE HUBS

Click on each icon to be taken to the corresponding Highest Good hub page.

One Community’s physical location will forward this movement as the first of many self-replicating teacher/demonstration communities, villages, and cities to be built around the world. This is the November 29th, 2020 edition (#401) of our weekly progress update detailing our team’s development and accomplishments towards helping people create a sustainable world:

Helping People Create a Sustainable World

One Community Progress Update #401

DONATE | COLLABORATE | HELP WITH LARGE-SCALE FUNDING

CLICK HERE IF YOU’D LIKE TO RECEIVE AN EMAIL EACH WEEK WHEN WE RELEASE A NEW UPDATE

YOU CAN ALSO JOIN US THROUGH SOCIAL MEDIA

ONE COMMUNITY WEEKLY UPDATE DETAILS

HIGHEST GOOD HOUSING PROGRESS

One Community is helping people create a sustainable world through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

One Community is helping people create a sustainable world through Highest Good housing that is artistic and beautiful, more affordable, more space efficient, lasts longer, DIY buildable, and constructed with healthy and sustainable materials:

-

-

- Learn about: Our Upcoming Crowdfunding Campaign

- Learn about the different village models: 7 Sustainable Village Models

- Visit the open source portals for the first two: Earthbag Village OS Hub | Straw Bale Village OS Hub

-

Dean Scholz (Architectural Designer) continued helping with the Earthbag Village (Pod 1) 4-dome cluster designs. This week was week #203 of Dean’s work and the focus was lighting levels and attempting to run final renders. Lighting levels were fixed so shadows weren’t so dark as to look black but now the renders are producing jagged lines where they should be straight, even though the pixel quality is higher. You can see some screenshots of this process below that contributes to the mission of helping people create a sustainable world.

Alvaro Hernández (Open Source Tech Consultant, Developer) completed his 33rd week as a member of the team and continued working on the Best Small and Large-scale Community Plastic Recycling, Repurposing, and Reuse Options tutorial. For this week Alvaro worked on the “Reducing Your Use of Plastics” section of the plastic article. He started the eco-flowchart for handling bottles at onecommunity and investigated PETG, R-PET filaments and another DIY filament extruder. As an extra, he also did some research on tire recycling due to his participation on an external hackathon.

Lastly he started the “Other Interesting plastic recycling options” section where he added the alternatives to transform plastic into food (yes, food… crazy) or into nanocarbon tubes+hydrogen. Pictures below show some of this work for helping people create a sustainable world.

Continued Working on Community Plastic Recycling, Repurposing, and Reuse Options Tutorial – Click for Page

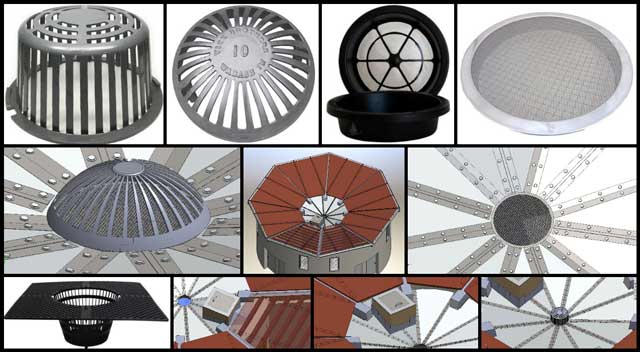

This week Jose Luis Flores (Mechanical Engineer) completed his 18th week helping finish the Net-zero Bathroom component of the Earthbag Village. This week Jose Luis updated the SolidWorks rendering of the Net-Zero Bathroom to include metal flashing covering the roof access along with the exterior roof support beams. He researched and rendered possible filters and grates to block debris and insects from entering the water supply. The metal flashing used on the roof access provides water sealing and water diversion. The exterior roof beams cannot be completely wrapped in the metal flashing and can be protected by a wood sealer.

The challenge with the insect and small debris filter was finding one large enough to fit the orifice of the roof, along with being easy to maintain and clean. The “Rain Harvesting Guardian” was found to provide the best benefits with minimum trade offs. There were a wide variety of dome grates used for filtering large debris, but the challenge was finding one that needed minimum modifications to fit over the roof orifice. The cylindrical drain dome strainer was found to be the simplest grate to retrofit while having sufficient gaps to allow water to flow through it. The pictures below show examples of some of this work towards helping people create a sustainable world.

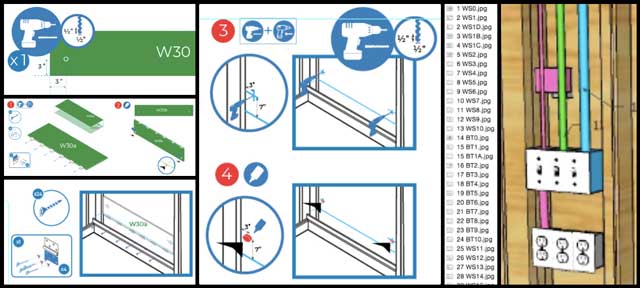

Stacey Maillet (Graphic Designer) completed her 17th week working on the final edits and revisions to the Murphy bed instructions. This week she made it on to page WS21, reworking many prior pages as she went. She also went back to the other sections and re-saved the views showing correct perspectives of the wall section. Pictures below show some of this work-in-progress.

Continued Working on Final Edits and Revisions to the Murphy Bed Instructions – Click for Furniture Page

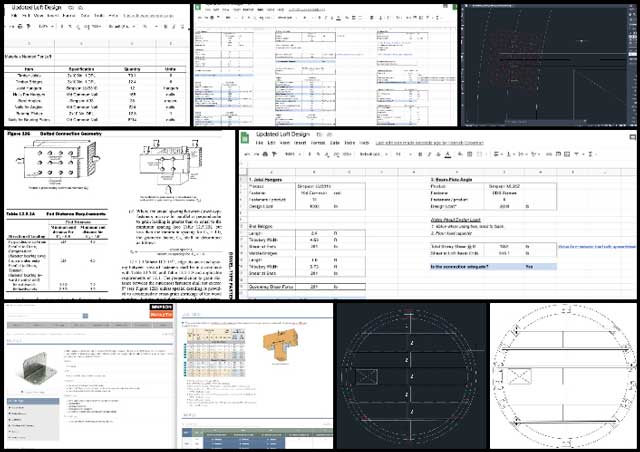

Hannah Copeman (Structural Engineer) completed her 15th week helping complete all the Earthbag Village tutorials. This week Hannah created an updated loft design to include timber beams, bridges and bearing plates as well as three connections: joist hangers for the bridges, steel angles to connect the beams to timber plates, and nails to connect the plates to the walls. In doing so, Hannah verified adequate spacing of the nails on each member, checked the relevant failure modes for each member, and created a preliminary materials needed list. You can see some screenshots of this work below for helping people create a sustainable world.

Alvin Anggito (BS Civil Engineering) also joined the team and completed his 1st week working on the Communal Eco-shower footer, foundation and flooring engineering. This week Alvin went through the orientation, familiarized himself with the existing research and files, and made a preliminary design in AutoCAD. The pictures below show examples of some of this work for helping people create a sustainable world.

DUPLICABLE CITY CENTER PROGRESS

One Community is helping people create a sustainable world through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

One Community is helping people create a sustainable world through a Duplicable and Sustainable City Center that is LEED Platinum certified/Sustainable, can feed 200 people at a time, provide laundry for over 300 people, is beautiful, spacious, and saves resources, money, and space:

-

-

- Learn about this building and it’s function: Duplicable City Center Open Source Hub

-

This week Ksenia Akimov (Plumbing Engineer) completed her 11th week working on the Duplicable City Center plumbing designs. This week Ksenia created the plan for the water supply and sewage systems in the kitchen. Pictures below show some of this work.

Created the Plan for the Water Supply and Sewage Systems in the Kitchen – Click for Duplicable City Center

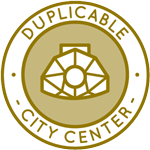

Lindy Rzonca (Sustainability Analyst) also completed her 8th week helping with sustainability research and now focused on the Best Small and Large-scale Community Options for Sustainable Processing and Reuse of Non-recyclables tutorial. This week, Lindy focused on combing through papers and online sources, and reading the work that the previous people did on the tutorial. Next week she will begin writing. Pictures below show some of what she reviewed.

Focused on the Best Community Options for Sustainable Processing and Reuse of Non-recyclables Tutorial – Click for Page

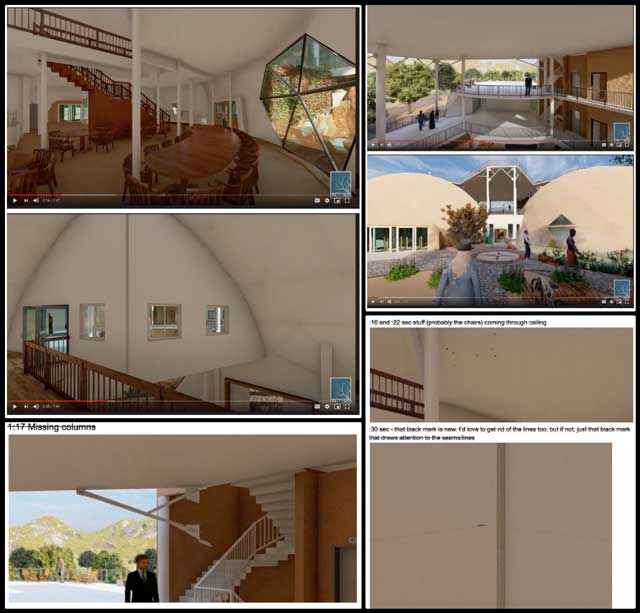

Qiuheng Xu (Landscape Designer) completed her 8th week helping with the Duplicable City Center landscaping design and updated video walkthrough. This week Qiuheng focused on further modifications in both the SketchUp file and Lumion file, checking off last week’s requested changes as she went. You can see some of the updated areas below.

Continued Helping With Duplicable City Center Landscaping Design and Updated Video Walkthrough – Click for Page

HIGHEST GOOD FOOD PROGRESS

One Community is helping people create a sustainable world through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

One Community is helping people create a sustainable world through Highest Good food that is more diverse, more nutritious, locally grown and sustainable, and part of our open source botanical garden model to support and share bio-diversity:

-

-

- Learn about the structures: Hoop House Hub | Aquapini & Walipini Open Source Hub

- See what we’ll be growing: Gardens & Hoop Houses | Large-scale Structures | Food Forest | TA

-

This week the core team continued with our new plan for the Transition Kitchen. We updated the foldable tables to match the equipment list, placed 24”x12” portable locking hard floor tiles, added an additional middle row of tables, and checked to confirm all appliances from the equipment list were in the SketchUp model. We also created a new “Materials Price List” spreadsheet.

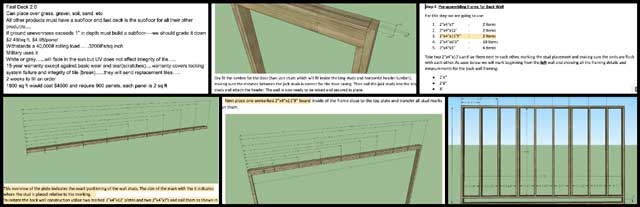

And we consulted with a representative of Big Floors, confirming the choice of Fast Deck 2.0 flooring for our transition kitchen and is seeking feedback from one of their end users who purchased Fast Deck 2.0. Pictures below show some of this work.

The core team also continued rewriting/finalizing the chicken coop doc step-by-step instructions. This week we reviewed and edited the coop doc through page 15, addressing numerous details helping with clarification for the wall construction. Pictures below show some of this behind-the-scenes work-in-progress for helping people create a sustainable world.

Jiayu Liang (Landscape Designer) completed her 9th week helping with the Aquapini & Walipini internal and external landscaping details. This week Jiayu continued making the outdoor model in Rhino. She finished the first half of the outdoor model, started researching the plant material on our website, and began making the test walkthrough in Lumion. Some pictures of this work-in-progress for helping people create a sustainable world are below.

Jingwei Jiang (Landscape Designer) also completed her 9th week working on the landscaping specifics of the Earthbag Village. This week Jingwei completed the first full SketchUp model for the Earthbag village landscaping and submitted it for review. Pictures of this work-in-progress for helping people create a sustainable world are below.

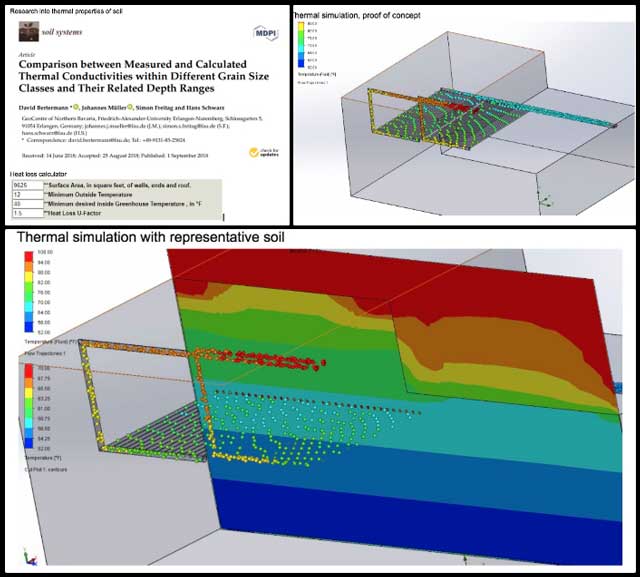

Henry Vennard (Mechanical Engineer) also completed his 8th week helping continue the development of the climate batteries for the Aquapini/Walipini structures. This week Henry got the climate battery simulations working in SolidWorks with simulated soil and began research on accurate inlet and outlet air. Once the air conditions are accurate the simulation should be complete and optimized for the greenhouse specifications. You can see some pictures related to this work for helping people create a sustainable world below.

Continued the Development of the Climate Batteries for the Aquapini/walipini Structures – Click for Page

Diana Gomez (Mechanical Engineer) also completed her 8th week helping continue the development of the climate batteries for the Aquapini/Walipini structures. This week Diana analyzed 3 climate batteries and compared their specs to our Aquapini/Walipini current design. She realized that increasing the number of subsystems will decrease the friction loss. The “Blue House” climate battery most closely resembled the Aquapini/Walipini design and the following specs: 7 pipes per subsystem = 147′ tubing and manifold + risers = 22′ tubing. Diana made two new configurations of the Aquapini/Walipini current design:

- 8″ manifold and 7 4″ pipes , -40 ft in manifold length for subsystem 1 and -20ft for subsystem 2.

- 10″ manifold and 7 4″ pipes , -40 ft in manifold length for subsystem 1 and -20ft for subsystem 2.

The friction loss for these configurations is calculated in the “Aquapini and Walipini Air Flow Rate Calculations” google sheet. The result was a friction loss of 4000 Pa – 5500 Pa but a 8-inch inline duct fan only provides ~350 Pa for a 241 cfm, meaning the fan cannot balance this system. Diana decided to calculate the friction loss in the “Blue House” and found that it was ~28,000 Pa which is significantly higher than the Aquapini/Walipini design. According to the “Blue House” analysis report, the system did not achieve turbulent flow but still provided 242,000 BTU in heating mode and 992,00 BTU in cooling mode. Although it was not an efficient system it still worked.

Diana then analyzed the effects of the diameter of the manifold and tubes on friction loss. This can be found in the “Aquapini and Walipini Air Flow Rate Calculations” google sheet under the “Blue House – friction loss” tab. The friction loss decreased exponentially as the diameter was increased. By increasing the manifold diameter and tube diameter by 1 inch the total friction loss decreased by ~70 in wg or ~1700 Pa. Diana will be creating new configurations of the Aquapini/Walipini climate battery (adjusting the diameter) to analyze the friction loss and provide them to Henry for heat transfer analysis. You can see pictures of some of this work-in-progress below.

Analyzed 3 Climate Batteries and Compared Their Specs to Our Aquapini/walipini Current Design – Click for Page

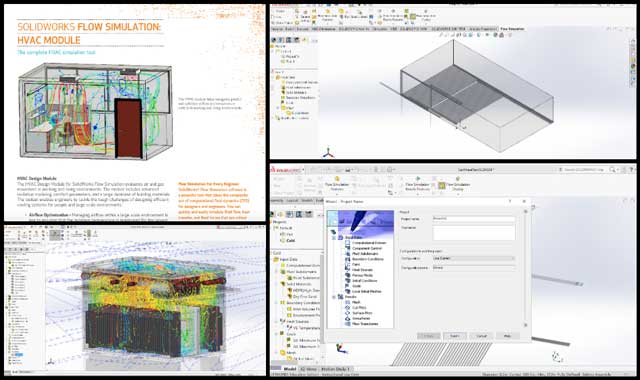

Reyes Mendoza (Mechanical Engineering Student) also completed his 6th week helping continue the development of the climate batteries for the Aquapini/Walipini structures. This week Reyes was able to get access to SolidWorks and is learning how to use flow simulation to apply it to our current design. He also worked on adding conversions into his Matlab code to make it easier to use regardless of the units being used. He additionally spent significant time trying to get the software working properly on his Mac, which requires a special Windows environment to run SolidWorks. You can see some pictures related to this work for helping people create a sustainable world below.

Got Access to Solidworks and is Learning How to Use Flow Simulation to Apply It to Our Current Design – Click for Aquapini:Walipini Page

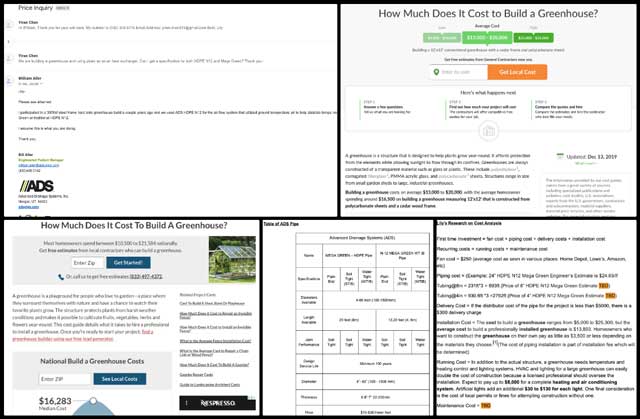

Yiran “Lily” Chen (Sustainability Coordinator) completed her 5th week helping continue the development of the climate batteries for the Aquapini/Walipini structures. This week Lily finished research on ADS pipe and provided a thorough table of ADS pipe kinds with attributes. In addition, Lily started working on the cost analysis based on previous research and then researching other costs approximations. You can see pictures related to this research for helping people create a sustainable world below.

Finished Research on ADS Pipe and Provided a Thorough Table of ADS Pipe Kinds With Attributes – Click for Aquapini:Walipini Page

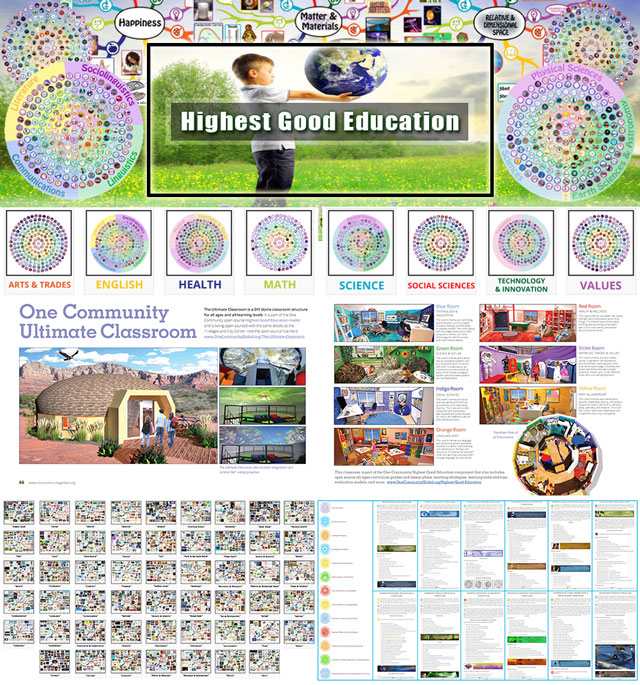

HIGHEST GOOD EDUCATION PROGRESS

One Community is helping people create a sustainable world through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students. This component of One Community is about 95% complete with only the Open Source School Licensing and Ultimate Classroom construction and assembly details remaining to be finished. We’ll report on the final two elements to be finished as we develop them.

One Community is helping people create a sustainable world through Highest Good education that is for all ages, applicable in any environment, adaptable to individual needs, far exceeds traditional education standards, and more fun for both the teachers and the students. This component of One Community is about 95% complete with only the Open Source School Licensing and Ultimate Classroom construction and assembly details remaining to be finished. We’ll report on the final two elements to be finished as we develop them.

With over 8 years of work invested in the process, the sections below are all complete until we move onto the property and continue the development and open sourcing process with teachers and students – a development process that is built directly into the structure of the education program and everything else we’re creating too such as helping people create a sustainable world:

- Program Overview: Education Open Source Hub

- How the components work together: How to use the Education for Life Program

- Lesson Plans for Life – Lesson Plans How-to

- Foundations of Outstanding Leaders, Teachers, and Communicators

- Curriculum for Life

- Teaching Strategies for Life

- Learning Tools and Toys for Life

- Evaluation and Evolution

Highest Good Education: All Subjects | All Learning Levels | Any Age – Click image for the open source hub

HIGHEST GOOD SOCIETY PROGRESS

One Community is helping people create a sustainable world through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

One Community is helping people create a sustainable world through a Highest Good society approach to living that is founded on fulfilled living, the study of meeting human needs, Community, and making a difference in the world:

-

-

- Read the Highest Good society overview: Highest Good Society

- Learn about the model for fulfilled living and sharing: A Day in the Life

- Learn about the 4 economic models: RBE | For-profit | Non-profit | Entrepreneurship

- Learn about our open source community collaboration and management software: The Highest Good Network

-

This week the core team completed 21 hours managing One Community emails, social media accounts, interviewing potential new volunteer team members, and managing volunteer-work review and collaboration not mentioned elsewhere here. Thus, contributing meaningful efforts towards helping people create a sustainable world.

The core team also continued working on the large-scale consensus content. This week we finished re-reading the Large-Scale Consensus content and made notes for things to re-check and links/anchors to add. We then began transferring the content to the web editor and this process is now about 2/3rds done. You can see some pictures of this behind-the-scenes work for helping people create a sustainable world below.

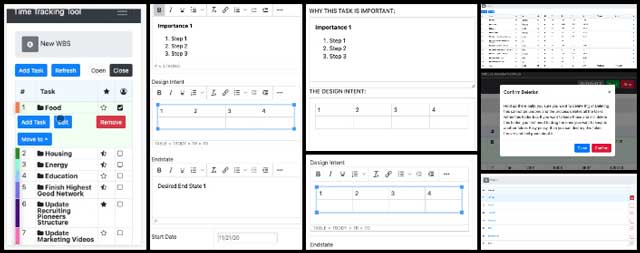

Henry Nguyen (React Developer) completed his 40th week with the team and working on the Highest Good Network software. This week Henry made the format for Why/Intent/Endstate so that Add, Edit, and View are now the same. He also added the editor tool set to it, so an Admin can add a table, bullets, text formatting, etc. He moved these to a new location too, then updated the permission for WBS and Task editing to Admins only. He also added a “confirm deletion” popup. The pictures below show some of this newly completed functionality catered towards helping people create a sustainable world.

Made the Format for Why/Intent/Endstate So That Add, Edit, and View Are Now the Same – Click for Highest Good Network

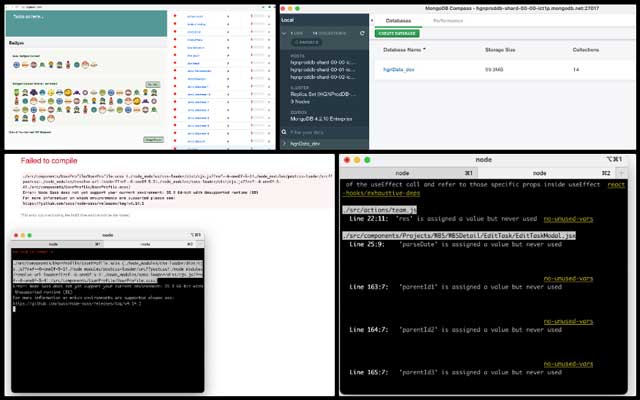

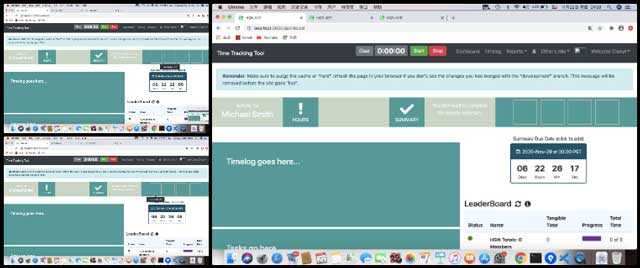

Wen Zhang (Software Engineer) completed her 26th week as a volunteer working on the Highest Good Network software. This week Wen is back to work with a new laptop! It took her about 3 hours to set up the dev environment and installed everything the HGN project needs (iTerm2, bash profile, IDE setting & extensions, global git, Node, MongoDB compass, etc.). The Node failed to compile at first. She solved the error and the app is now running successfully on her local. She rewrote some work-in-process code that she didn’t commit to git and lost from her last laptop focused on helping people create a sustainable world.

In the coming week, she will finish reproducing the testing data, wrap up what she has and create a PR, as the planned MVP launch is a few days away. Pictures of some of this work towards helping people create a sustainable world are below.

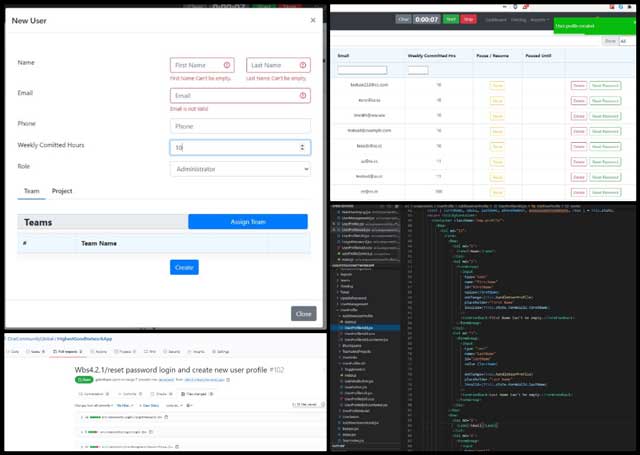

TEKtalent Inc. (a custom programming solutions company) also continued with their 25th week helping with the Highest Good Network software. This week Nithesh and the TEK Talent team completed the create new user profile functionality and the validations. Now Admins can create a user profile, can see the users and do all other actions in the user management area. Pictures below show some of this new functionality that contributes to the mission of helping people create a sustainable world.

Completed The Create New User Profile Functionality and The Validations – Click for Highest Good Network

Yiqi Feng (Software Engineer) continued with her 18th week as a member of the Highest Good Network software team. This week Yiqi moved the bar to the top of the page. She Added space between badges and adjusted the size of words and icons. She found the right size of badges should be 85x85px. Yiqi also implemented the notification function for “Tasks” and “Badge Earned” and finished the initial click function setup for the “Blue Squares” icon. You can see some pictures related to this work towards helping people create a sustainable world below.

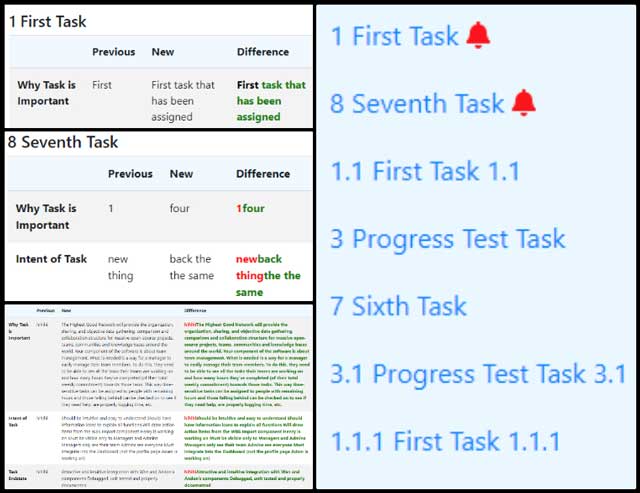

Jerry Zhang (Software Engineer) completed his 13th week working on the Highest Good Network software. This week Jerry changed the notification modal UI as so the previous and current state of task infos are shown, as well as a third field highlighting their differences. Modal UI for editing tasks was also made slightly larger to accommodate entering task infos. Pictures are below showing some of this work towards helping people create a sustainable world.

Changed the Notification Modal UI as So the Previous and Current State of Task Infos Are Shown – Click for Highest Good Network

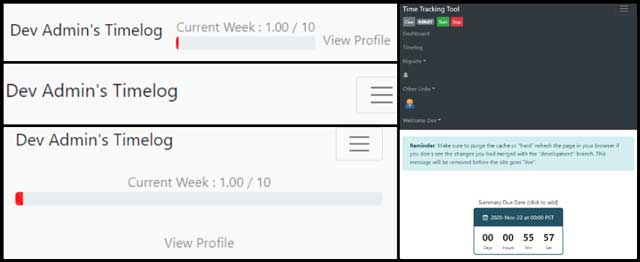

Chris Weilacker (Software Engineer) completed his 13th week working on the Highest Good Network software. This week Chris worked on the navigation toggle buttons getting them to work properly when they are clicked both for the header and timelog sections. Chris also worked on having the timelog entry popup be on intangible time by default if on mobile view for the timer or manually adding an entry to the timelog, unless the user is an Admin. Pictures related to this work towards helping people create a sustainable world are below.

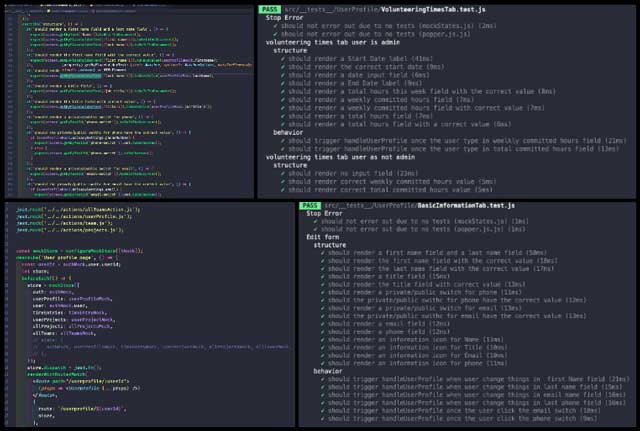

Jun Hao (Software Engineer) also completed his 12th week working on the Highest Good Network software. This week Jun was mainly working on cleaning up the code for the user profile component, writing unit tests, and fixing bugs. Specifically, Jun split the user profile into sub modules, so the future code maintenance and feature extension can be easier. He finished all the unit tests for the submodules and the only unit tests he left is the integrated test for the whole user profile component. You can see some of this work below catered towards helping people create a sustainable world.

Mainly Worked on Cleaning Up the Code for the User Profile Component – Click for Highest Good Network

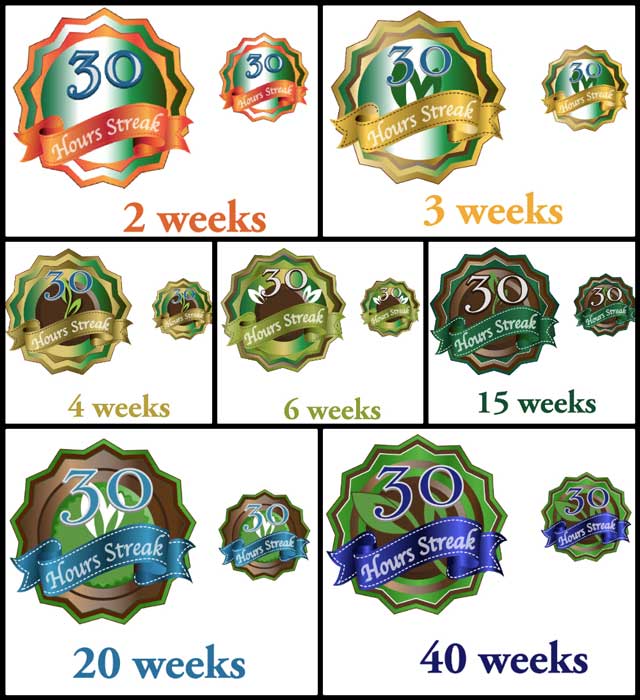

Jaime Arango (Graphic Designer) also completed his 11th week helping with various graphic design work for the project, continuing work on the new badges for the badges section on the Dashboard of the Highest Good Network. This week’s focus was making design and size corrections on the badges he created last week and figuring out ways to compress the files without compromising the definition of the images, making contributions towards helping people create a sustainable world. Pictures of the updated badges are below.

AND WE PRODUCED THIS WEEKLY UPDATES BLOG – CLICK HERE TO SUBSCRIBE

FOLLOW ONE COMMUNITY’S PROGRESS (click icons for our pages)

INVESTOR PAGES

GET INVOLVED

DONATE ● WAYS ANYONE CAN HELP ● MEMBERSHIP

CLICK HERE FOR ALL PAST UPDATES

HELPING PEOPLE CREATE A SUSTAINABLE WORLD –

WHAT ONE COMMUNITY IS CREATING

One Community is creating a place to grow together and change the world together by helping people create a sustainable world. We are creating a space that helps each other live in integrity with each other and the planet as we strive to be the greatest versions of ourselves. We do this by harmoniously respecting each other, nature, and the rest of our one shared planet.

Our goal is to demonstrate what we feel is the most sustainable, healthy, and fun environment we can create. A place based on compassion, kindness, and collaboration. This replicable community will serve as an example for what is possible.

Throughout our design process of helping people create a sustainable world we are open sourcing and free-sharing everything needed for construction and replication. This includes what we call “Highest Good” approaches to food, energy, housing, education, for-profit and non-profit economics design, social architecture, fulfilled living, stewardship practices and more. We are creating these resources for implementation as individual components or complete developments called teacher/demonstration hubs for helping people create a sustainable world. These hubs will help launch additional hubs as awareness and knowledge grow.

HELPING PEOPLE CREATE A SUSTAINABLE WORLD – BUILDING THE FIRST OF MANY

One Community will be the first teacher/demonstration hub for helping people create a sustainable world. It will function as an experiential-learning model that facilitates mass participation to address humanity’s most pressing challenges through: A replicable model for expansion, building seven self-sufficient village/city prototypes, becoming the world leader in open-source sustainability solutions, and evolving and expanding ALL aspects of sustainable living such as helping people create a sustainable world.

HELPING PEOPLE CREATE A SUSTAINABLE WORLD – WHY ONE COMMUNITY IS CREATING THIS

The One Community self-replicating model of helping people create a sustainable world is capable of creating a sustainable planet within 30 years. We will achieve this by establishing successful teacher/demonstration hubs on every continent. Villages include designs appropriate for each of the five main types of climates. They also include options for even the most challenged economies. These hubs will collaborate with one another, share ideas, resources, and work together as a network to heal the planet. They will also transform the global lifestyle to a more enjoyable, fulfilling, healthy, and sustainable one.

The specifics of how One Community is accomplishing this helping people create a sustainable world model can be found on the One Community Solution Model to Create Solution-creating Models Page. Research supporting and showing the benefits of a model like this can be found on our Research and Resources Articles Archive.

Even if we don’t achieve our ultimate goal of global transformation such as helping people create a sustainable world, a self-replicating teacher/demonstration model like this will take a relatively short period of time to positively affect millions while inspiring millions more. For One Community residents (the Pioneer Team), the idea of creating and sharing the social and recreational experience with visitors is also fun, exciting, fulfilling, and an additional reason why we are helping people create a sustainable world.

One Community

One Community

Connect with One Community